Build your own boat

|

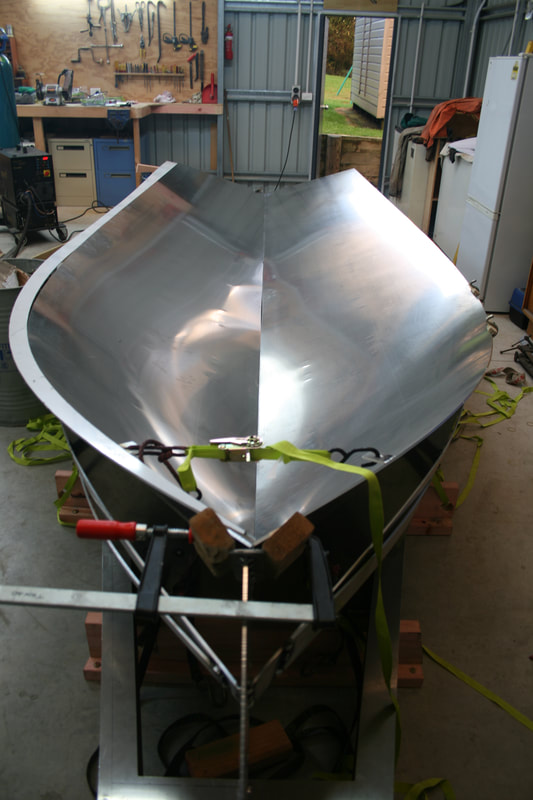

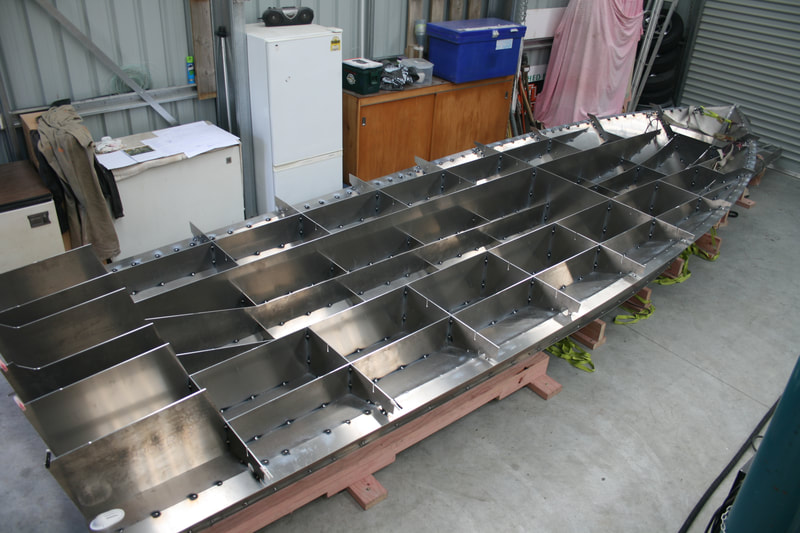

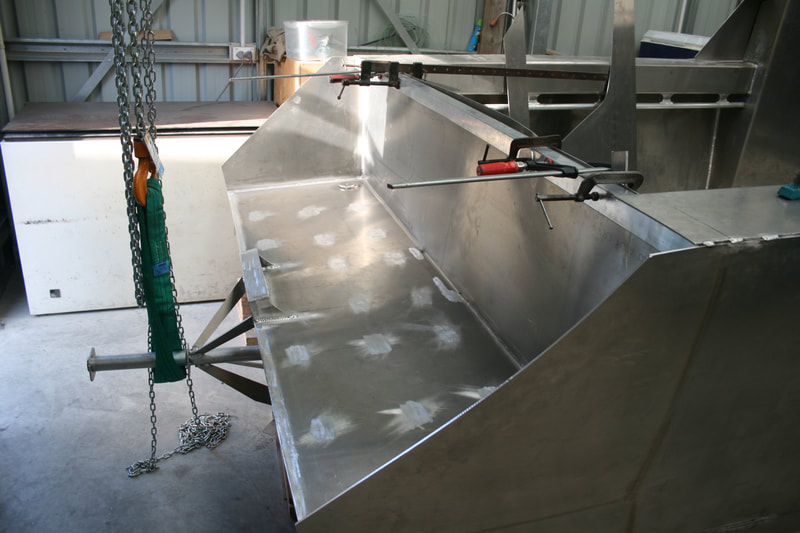

The kit set has three parts, the building jig, the alloy flat-pack and the plans. The building jig comes as a flat-pack and the first part of the construction is to erect the building jig. The jig is all self aligning and once assembled is just levelled and fastened to the floor. Constructing the jig is less than a mornings work. We now have two style of jigs. The traditional customwood jig and the alloy jig that becomes the trailer which is now the most popular. Why do we use the building jig? From a building perspective, after 35 years as a qualified boatbuilder, I know that it is the best way to assemble the boats, resulting in a first class, accurate build, even by first time builders. The small cost of the jig is recouped by the higher re-sale value of a quality product. From a design perspective, it enables us to create the perfect hull shape, and the use of the jig makes it achievable for builders to then accurately build this superior hull shape. By providing the female jig building system as part of the kit, clients can easily build to our refined hull shapes, and thereby get the best alloy hull available. Just ask anyone who's been on one! Once the skins are in place, all the structure is tacked in before any major welding commences. This way, all the parts fit together perfectly which greatly reduces the time to build and enhances the accuracy. Once welding commences, all welds are downhand welds making the process easier and more accurate, especially for first time builders. The plans compliment the pre-cut jig and the pre-cut alloy flat-pack to make the process easy and accurate. The picture shown are from builder Grant Crail showing consruction of his 701 short cabin outboard boat "Azure" Cheers Grant for the pictures. Grant was a first time builder and check out the results, Absolutely superb! He used the alloy trailer/jig and loves the result. You end up with a very light but strong and durable trailer which is a dream for towing, launching and retrieval. Compliments the boat perfectly. |